Purified Terephthalic Acid (PTA) Production Capacity reach to 83.8 million Tons in 2018

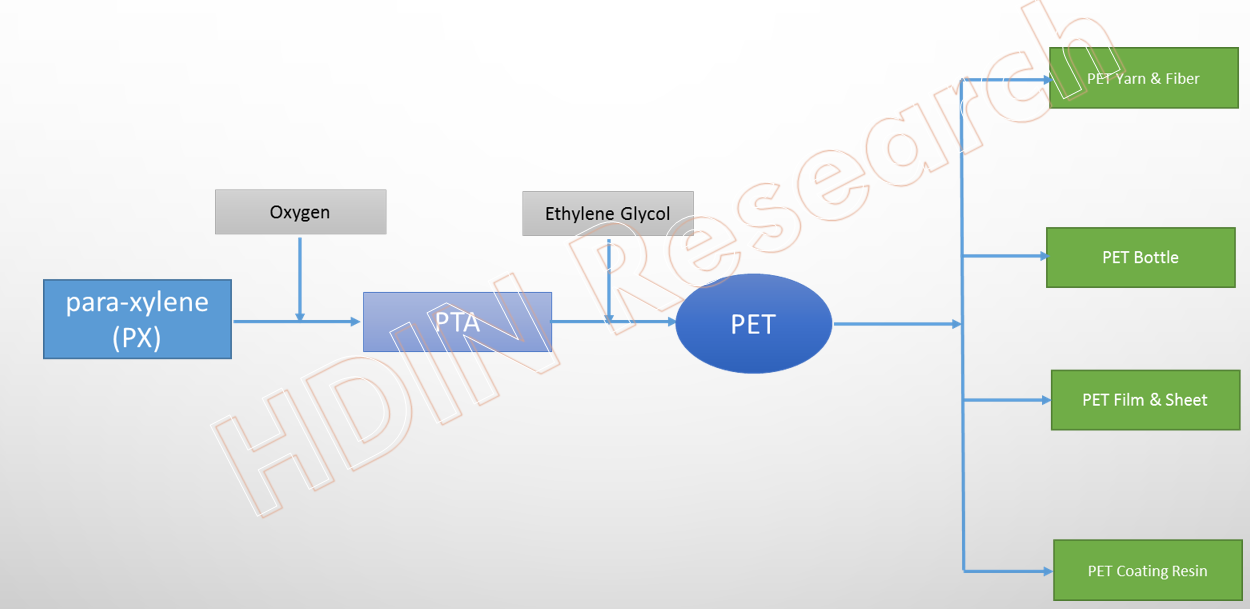

PTA is a very important commodity chemicals which can be used to produce polyester (PET)-a very import polymer which can be made to fiber, yarn, bottle, film, sheet etc.

Figure PTA Industrial Chain

Source: HDIN Research

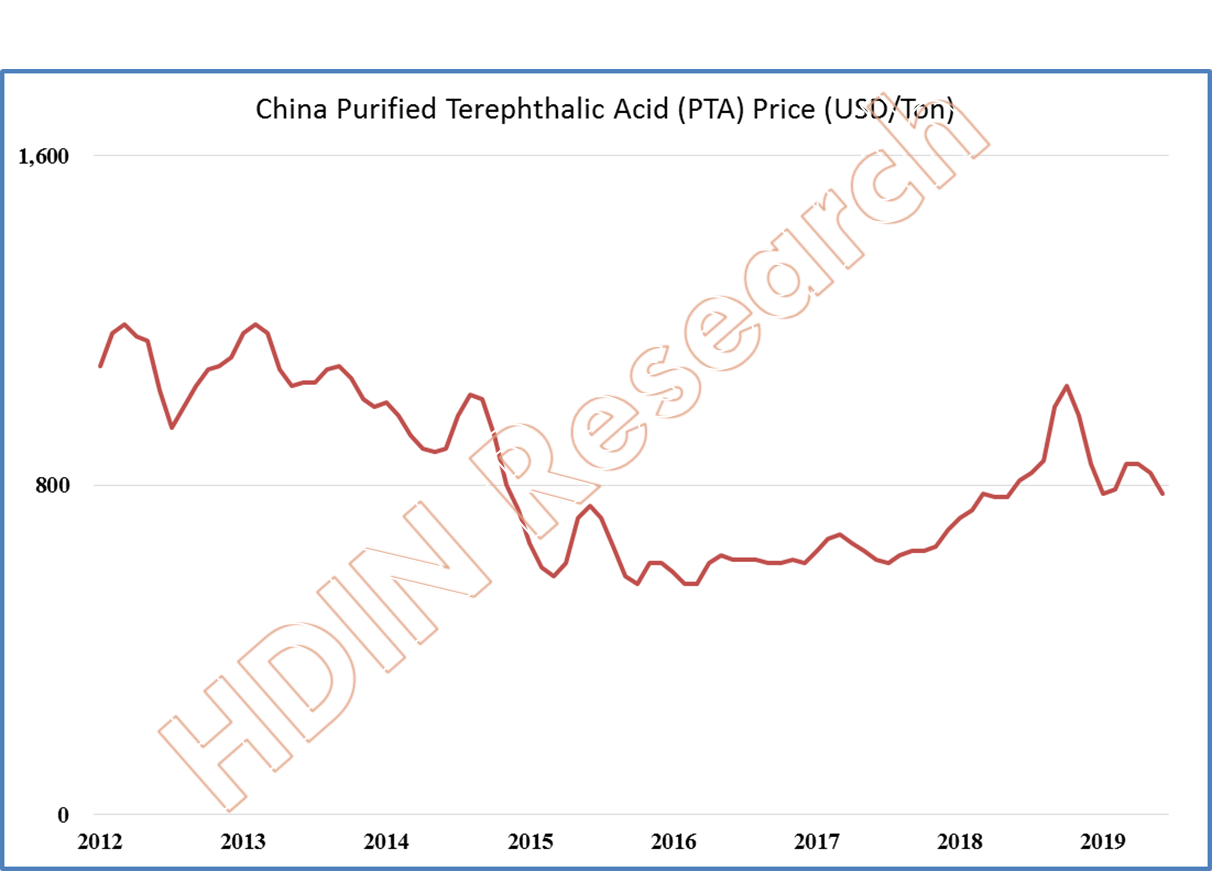

The para-xylene (PX) is a very import raw material for PTA production, and the PX is made by separating compound xylene which is usually from petroleum. So the price of PTA heavily depend on petroleum price.

Figure 2012- 2019 China PTA Price (USD/Ton)

Source: HDIN Research

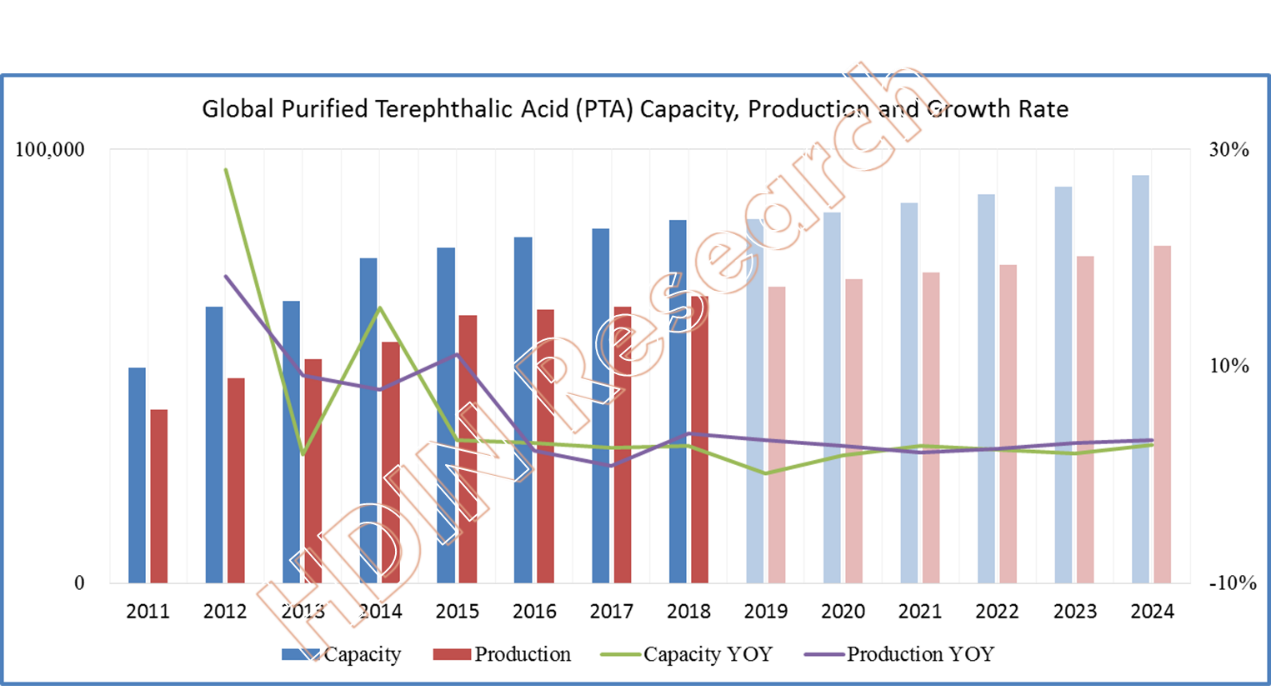

The global PTA production capacity and production volume reaches to 83.8 million tons and 66.1 million tons at 7.7% and 7.5% CAGR from 2011 to 2018 respectively. And the capacity and production will reach to 94.0 million tons and 77.8 million tons in 2024.

Figure 2011-2024 Global PTA Production Capacity, Production and Growth Rate

Source: HDIN Research

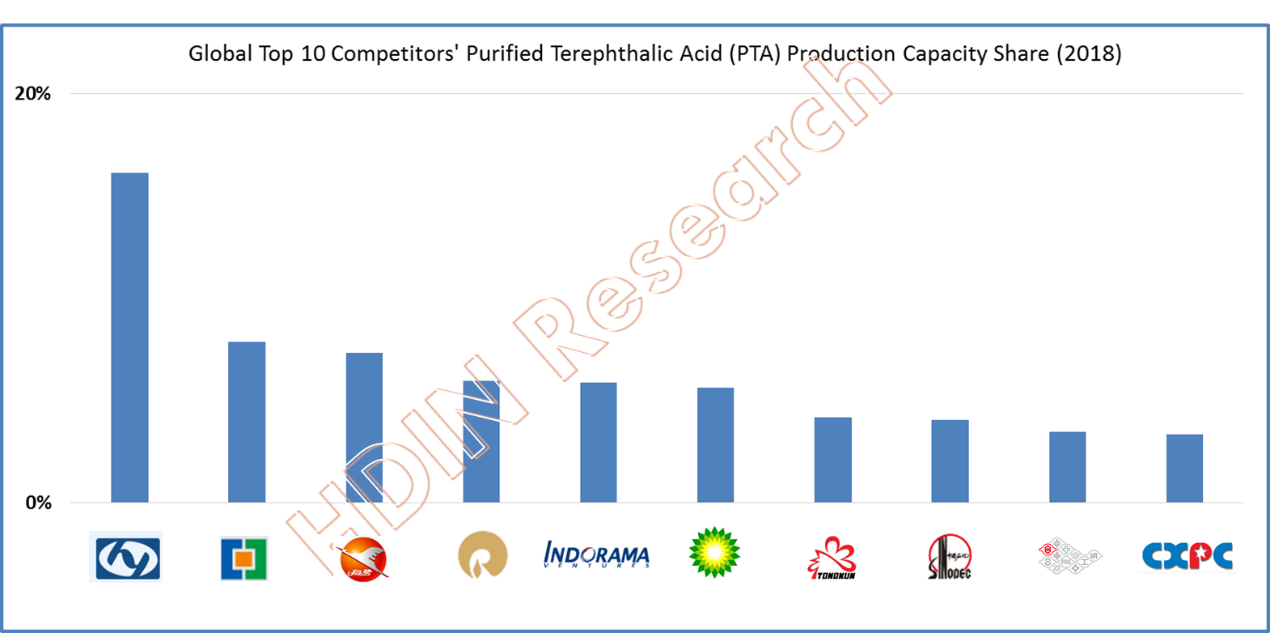

Global top 6 PTA manufacturers are YiSheng, Hengli Petrochemical, Xianglu Petrochemical, Reliance Industries, Indorama and BP, and their production capacity share reach to 48.8% of global total capacity in 2018.

Figure Global Top 10 PTA Competitors Market Share

Source: HDIN Research

Source: HDIN Research

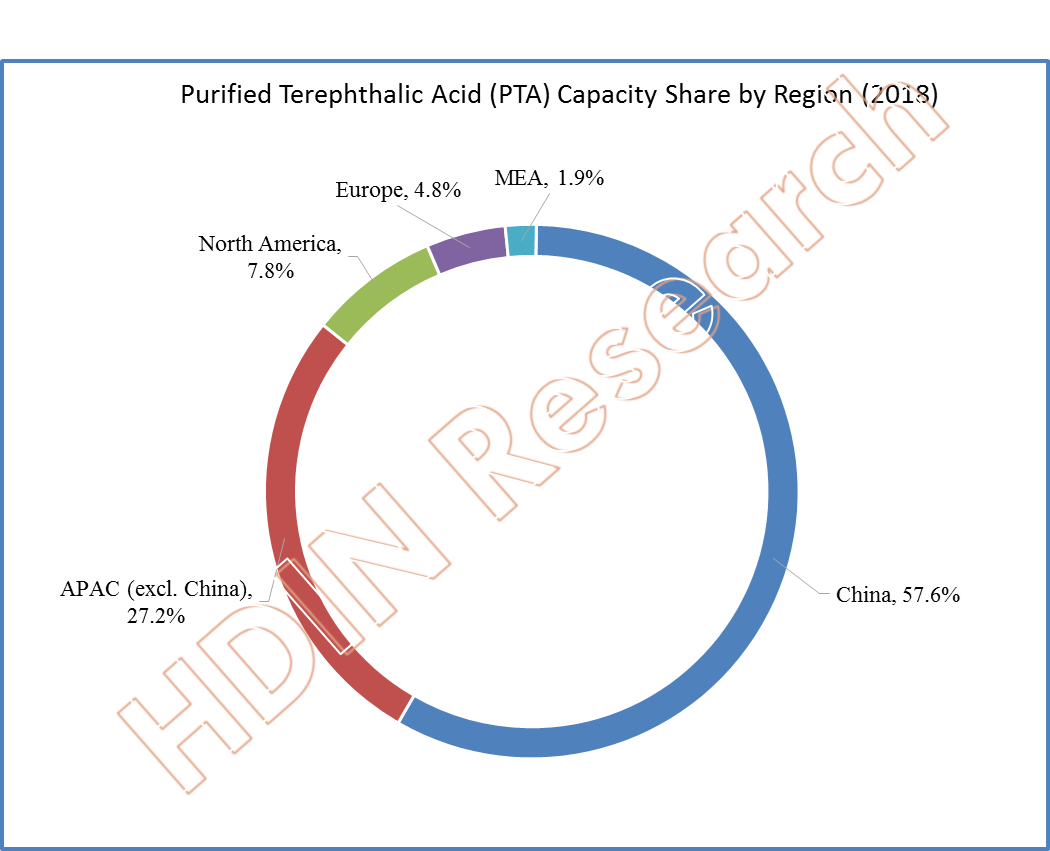

China is the largest PTA production and consumption country with 48.3 million tons installed capacity, following by APAC (excl. China, 22.8 million tons), North America (6.6 million tons), Europe (4.0 million tons), MEA (1.6 million tons) and South America (0.6 million tons).

Figure PTA Production Share by Region

Source: HDIN Research

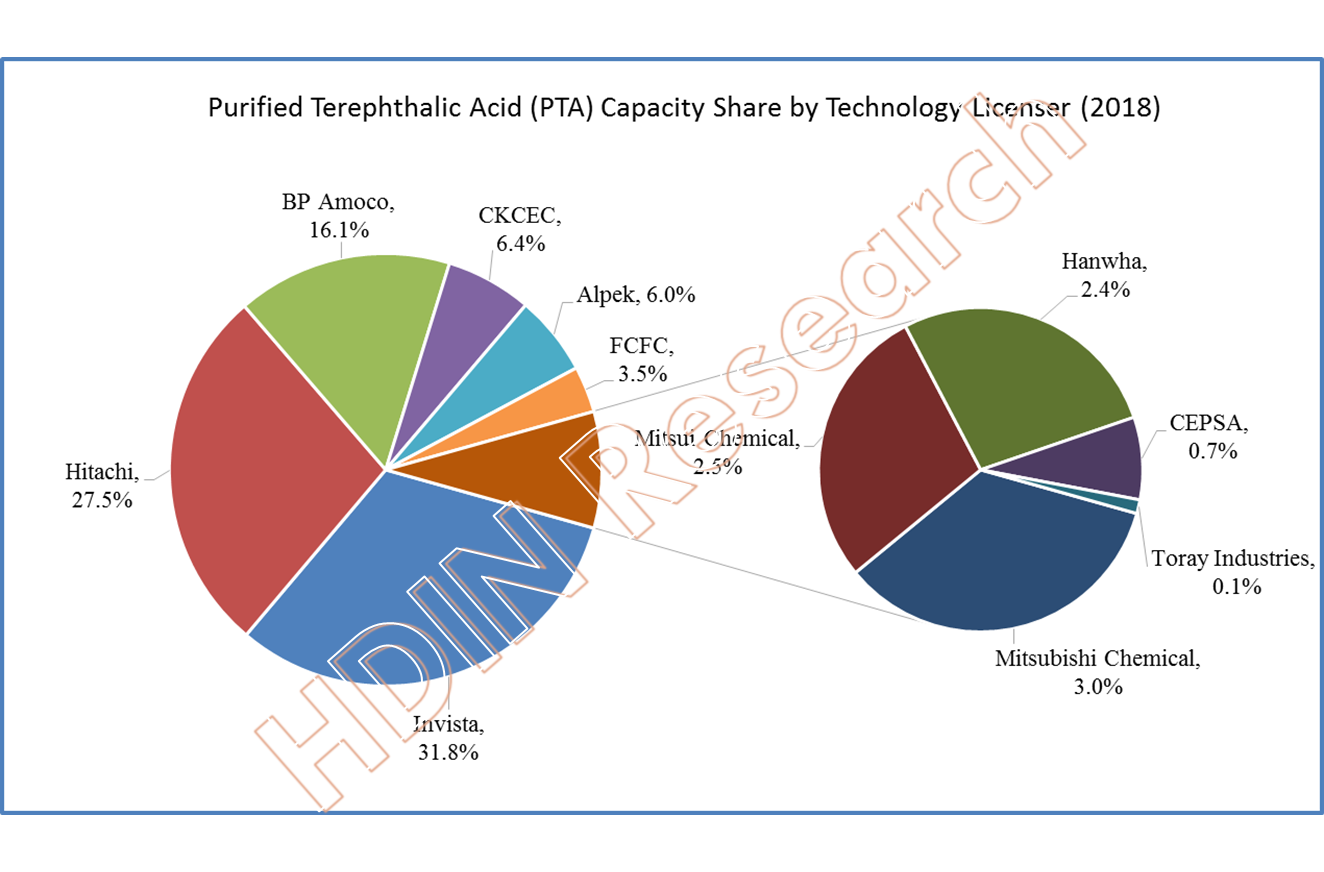

Invista, Hitachi, BP Amoco, China Kunlun Contracting and Engineering Corporation (CKCEC), Alpek are the key technology licenser of PTA. The installed capacity share by technology licenser is showing as follows:

Figure Purified Terephthalic Acid (PTA) Capacity Share by Technology Licenser until 2018

Source: HDIN Research

This report also include global and regional PTA consumption, market size, price, raw materials and cost analysis, demand by application including PET Yarn & Fiber, PET Bottle, PET Film & Sheet, PET Coating Resin.