Chemical Mechanical Polishing (CMP) Pad Producers and Market Trend

CMP technology is a process that causes the material to be polished to achieve the required flatness of the material surface by a combination of chemical and mechanical action. The chemical components in the polishing solution react chemically with the surface of the material to form a softened layer that is easy to polish. The polishing pad and the abrasive particles in the polishing solution physically and mechanically polish the surface of the material to remove the softened layer. CMP polishing pad types can be according to the material structure mainly: polymer polishing pads, non-woven polishing pads, non-woven polishing pads with lint structure, composite polishing pads.

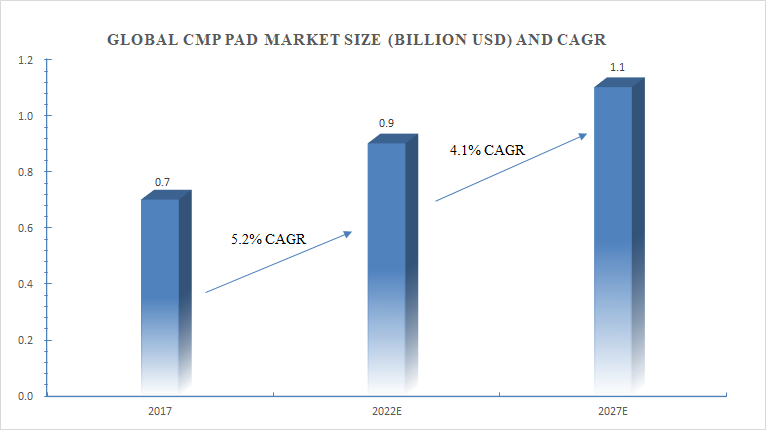

The global CMP Pad market size was USD 700 million in 2017 and will grow to USD 900 million in 2022, with a CAGR of 5.2% from 2017 to 2022. The global CMP Pad market size is expected to grow to USD 1.1 billion in 2027, with a CAGR of 4.1% from 2022 to 2027.

Figure 2017-2027 Global CMP Pad Market Size (Billion USD) and CAGR

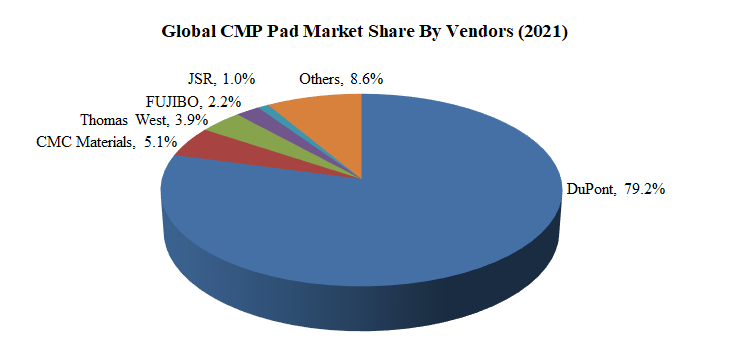

The global CMP pad market is currently dominated by DuPont with a market share of nearly 80% in 2021, while other suppliers include CMC Materials (5.1%), Thomas West (3.9%), FUJIBO (2.2%), and JSR (1.0%).