Photovoltaic Silver Paste Producers and Photovoltaic Silver Paste Market Trend

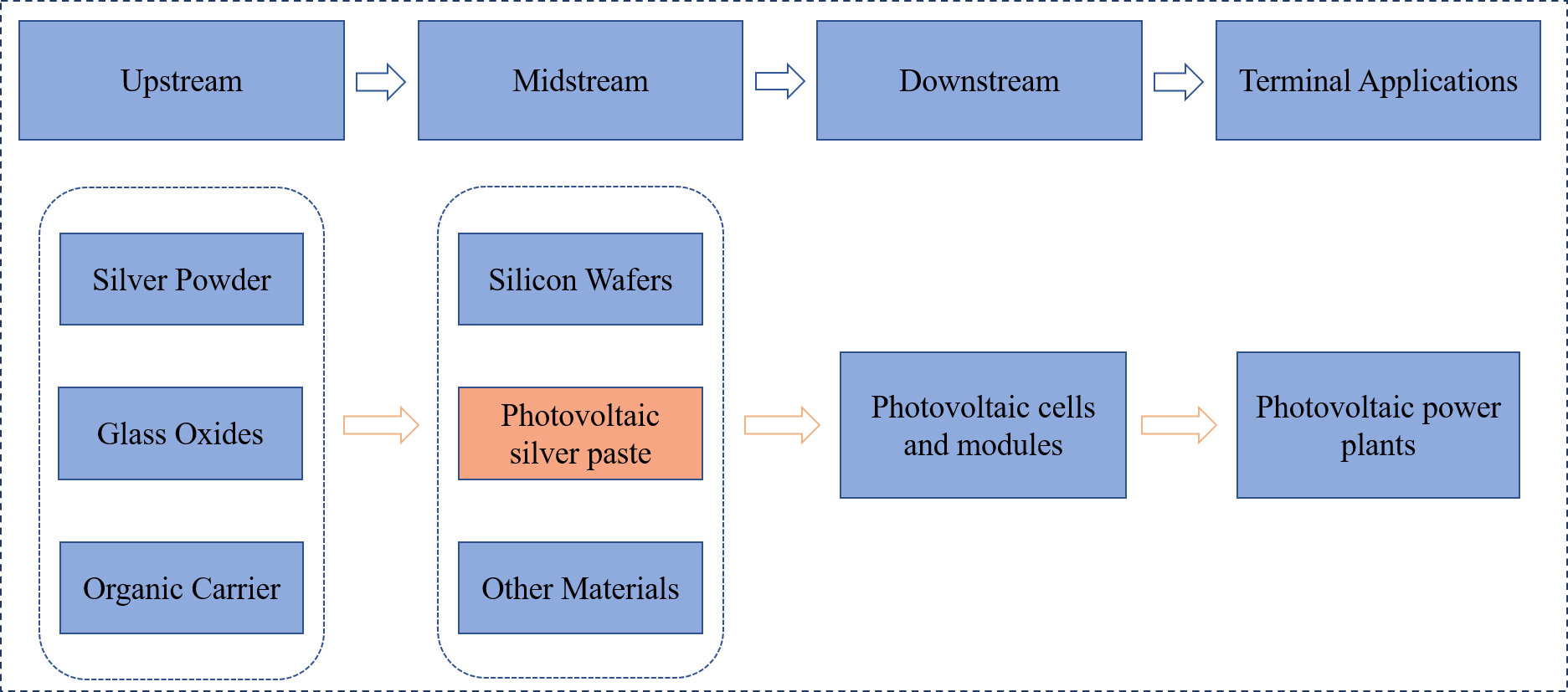

Photovoltaic silver paste is a mixture of high purity silver powder as the conductive phase, glass oxide as the binder phase, and organic carrier. They are formed into a uniform paste after stirring and three-roll rolling. The photovoltaic silver paste is attached to the photovoltaic cell sheet through the screen printing process, and after drying and sintering, it forms the metal electrode of the photovoltaic cell, which can collect and conduct the current on the surface of the photovoltaic cell. Conductive silver paste is the most important auxiliary material for photovoltaic cells, directly affecting the cell photoelectric conversion efficiency. At present, silver paste accounts for about 10% of the cost of photovoltaic cells.

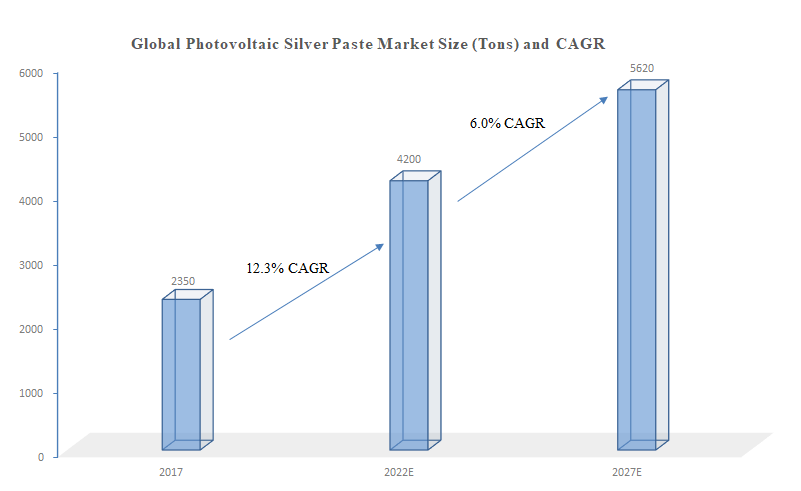

The global market size of photovoltaic silver paste increases from 2,350 tons in 2017 to 4,200 tons in 2022, with a CAGR of 12.3% from 2017 to 2022. Driven by the surging demand of the solar energy industry supported by China, the US, European government, the global market size of photovoltaic silver paste is expected to reach 5,620 tons in 2027, with a CAGR of 6.0% from 2022 to 2027.

Global photovoltaic silver paste major manufacturers are DK Electronic Materials Inc (DKEM), Heraeus, Samsung SDI, Giga Solar, Suzhou silver Materials, Chang Sung Corporation, Solarium, Shanghai TransCom, Changzhou Fusion, Jiangsu Hoyi, RightSilver, Zhejiang Gonda Electronic Technology.

The upstream of photovoltaic silver paste is silver powder, glass oxide, and organic carrier. The downstream of photovoltaic silver paste are the solar cell and solar cell module. The global photovoltaic industry's long-term development prospects will keep rapidly growing due to clean energy and carbon neutrality supported by global governments. The following is the photovoltaic silver paste industry chain diagram.